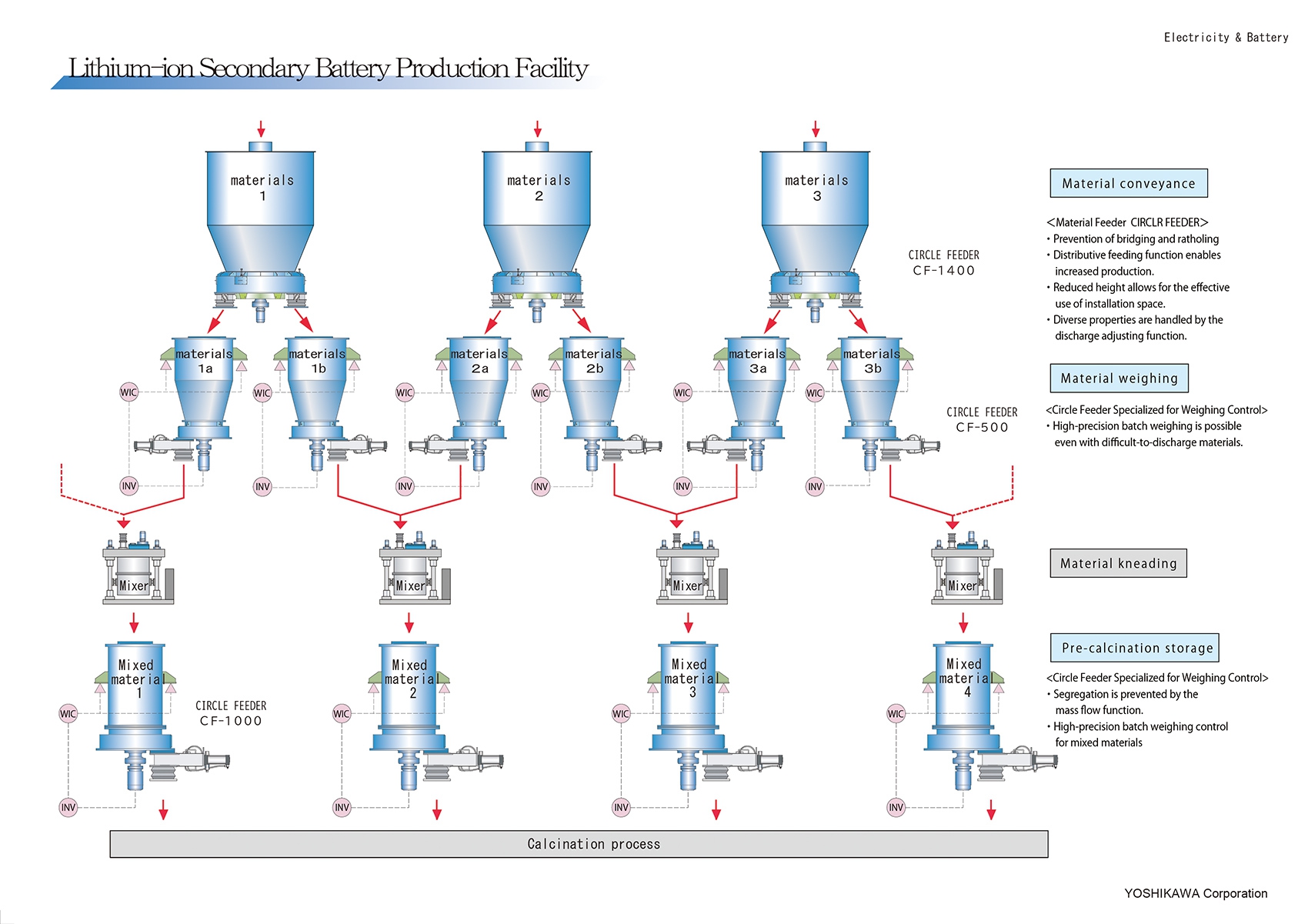

Lithium-ion Secondary Battery Production Facility

Facility outline

High performance and technology for safety, high output power, longevity, etc. are required for lithium-ion secondary batteries.

In the lithium-ion secondary battery production line, Circle Feeders are used in the transport, weighing and other processes, as well as in buffer tanks between processes.

The production of secondary batteries involves a wide variety of processes, including the mixing of materials, calcination and pulverization.

The Circle Feeder has been integral to these diverse processes, as a feeder that eliminates bridging and segregation.

Manufacturing Flow

1.Material conveyance

Material Feeder CIRCLR FEEDER

- Prevention of bridging and ratholing.

- Distributive feeding function enables increased production.

- Reduced height allows for the effective use of installation space.

- Diverse properties are handled by the discharge adjusting function.

2.Material weighing

Circle Feeder Specialized for Weighing Control

- High-precision batch weighing is possible even with difficult-to-discharge materials.

3.Material kneading

4.Pre-calcination storage

Circle Feeder Specialized for Weighing Control

- Segregation is prevented by the mass flow function.

- High-precision batch weighing control for mixed materials